In regulated industries, compliance isn’t just a checklist — it’s a constant state of readiness. Whether you’re labeling pharmaceuticals, food products, or electronics, a single misprint can trigger recalls, fines, or lost trust.

This is why ZPL validation has become an essential part of modern compliance workflows. Companies are no longer waiting to discover labeling errors on the production line — they’re catching them upstream, before the label ever gets printed.

And at the center of this shift is ZPL.ai, a cloud-based validation and preview system built to ensure every label meets compliance standards before it leaves the screen.

The Stakes of Non-Compliance

Labeling regulations affect nearly every industry. From FDA 21 CFR Part 11 in pharmaceuticals to GS1 data matrix standards in retail, compliance now extends down to font size, barcode readability, and character encoding.

Even a simple formatting mistake — like a truncated batch number or wrong expiration date — can cause:

- Regulatory audits or penalties.

- Delayed shipments.

- Rejected products in distribution channels.

One medical device manufacturer reported losing $250,000 in one quarter due to labeling rework caused by inconsistent printer calibration.

These are preventable issues — and that’s exactly where ZPL validation enters the picture.

Understanding ZPL Validation

ZPL (Zebra Programming Language) controls how printers interpret and render label data. Validation means testing that ZPL output matches compliance rules before it’s sent to a printer.

ZPL.ai automates this process by running pre-print validation checks, ensuring:

- Correct barcode format (GS1, Code128, QR).

- Accurate label dimensions for specific printers.

- Verified font size and character encoding.

- Complete data mapping from ERP or MES systems.

Instead of reacting to failed prints, compliance teams gain full visibility and confidence in their output.

Automating Compliance in the Cloud

In traditional setups, compliance testing happens post-print — inspectors manually check labels, scan barcodes, and sign off batches.

That’s slow, costly, and prone to human error.

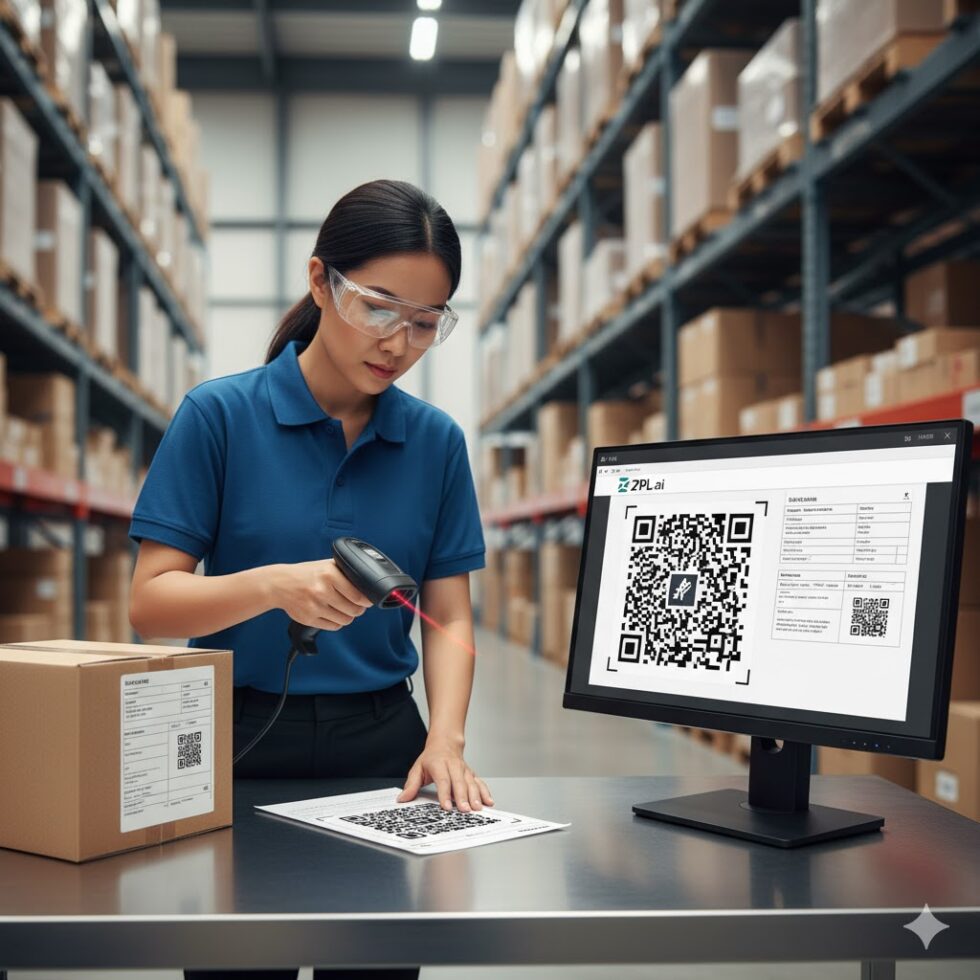

With ZPL.ai, validation moves upstream and online. The system automatically runs label previews and validation scripts through its API before any label is printed.

What that means for organizations:

- Every print job gets automatically checked.

- Visual and technical errors are caught early.

- Digital audit trails are stored for every batch.

- Multi-site consistency is finally achievable.

For multi-location enterprises, cloud validation replaces fragmented local workflows with a single, centralized compliance layer.

Industry Use Cases

- Pharmaceuticals: ZPL.ai ensures dosage data and barcodes comply with FDA serialization standards.

- Food & Beverage: Expiration and lot codes are validated for traceability.

- Manufacturing: Product labels meet ISO and GS1 barcode placement requirements.

- Logistics: Carrier-compliant shipping labels (FedEx, UPS, DHL) are verified before printing.

The Role of APIs in Modern Compliance

ZPL.ai’s API integration allows developers to connect validation checks directly into their existing systems — ERP, MES, or WMS.

A new print job automatically triggers:

- Label rendering in the cloud.

- Validation rules against compliance parameters.

- Approval or rejection notifications.

This ensures compliance isn’t dependent on human oversight — it’s built into the workflow itself.

Measurable Impact

After integrating automated ZPL validation, companies typically report:

| Metric | Before | After ZPL.ai |

| Label rejection rate | 3.7% | 0.2% |

| Audit prep time | 4 days | < 1 hour |

| Compliance deviation reports | 28/year | 3/year |

| Average print error recovery | 15 min | Instant |

For global manufacturers and logistics networks, this translates into millions saved annually through avoided waste, reprints, and penalties.

Final Thoughts

Label compliance isn’t optional anymore — it’s a foundational part of supply chain integrity.

By validating ZPL output before it reaches the printer, companies move from manual inspection to automated assurance.

ZPL.ai turns what used to be a post-print headache into a proactive compliance advantage.

To ensure every label you print meets regulatory standards and customer expectations, test your templates in the zpl viewer before going live — the fastest way to stay compliant and confident.